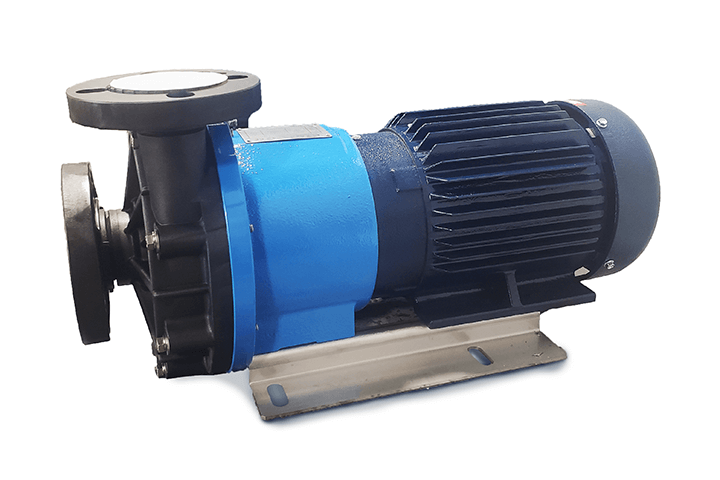

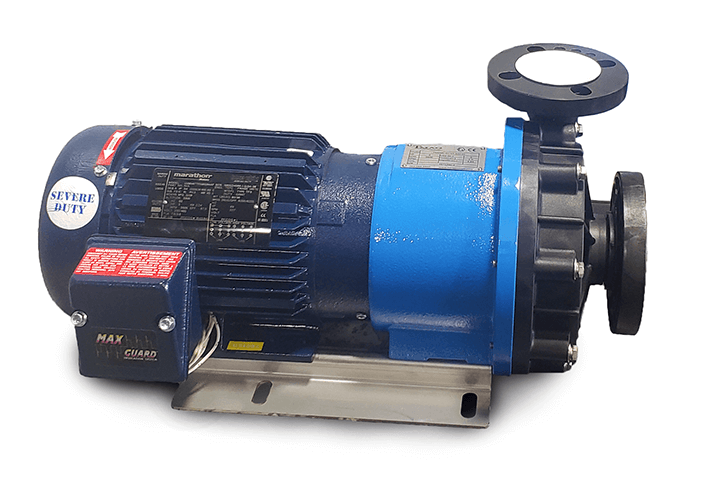

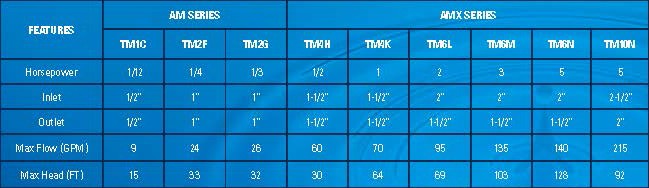

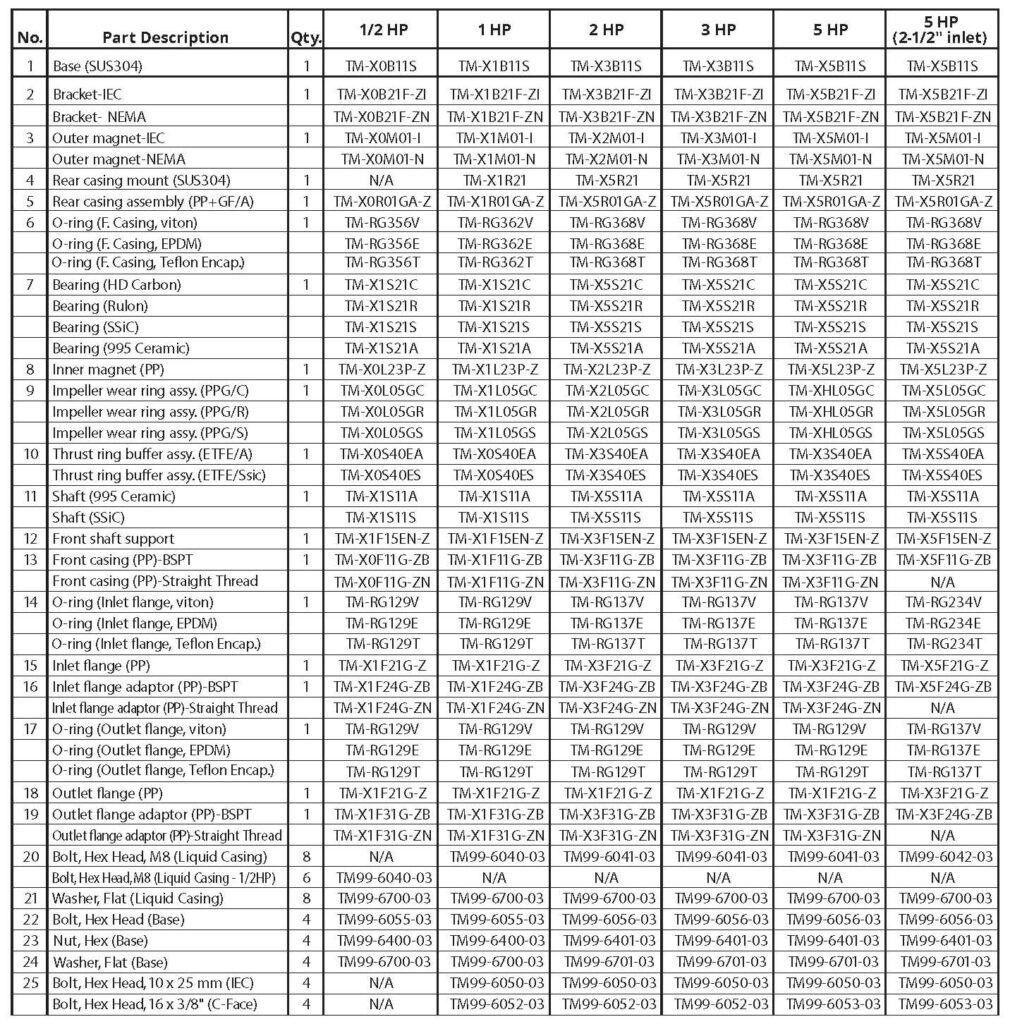

The AMX Series Mag Drive Pump leaps ahead of the competition with the latest heat dissipation technology and six horsepower ratings to choose from. The AMX Series mag drive pump offers some of the highest flow rates seen in the industry. Ultimately this pump will bring you increased productivity, reduce operational costs & downtime and provide peace of mind. The AMX Series Mag Drive Pump has six sizes to choose from: 1/2, 1, 2, 3, and two 5 HP options. Available in Polypropylene and ETFE, the AMX Series Centrifugal Sealless Mag Drive Pump will fit almost any application.

T-Mag pumps are designed to meet the performance requirements of even the most demanding pumping applications. They have been designed and manufactured to the highest standards and are available in a variety of liquid path materials to meet your chemical resistance needs. A T-Mag Mag Drive Pump is ideal for transferring acids, alkalis, hydrocarbons, heat transfer oils, liquid gases, toxic and explosive chemicals in industrial and chemical industries. They are also suitable for pumping low viscosity surfactants, acids and CIP chemicals in pharmaceutical and cosmetic industries. In the food and drink industries they are ideal for handling CIP chemicals, such as sodium hydroxide, nitric acid and hydrogen peroxide and pumping water treatment chemicals.

Each and every product assembled by T-Mag Pumps is built to meet the highest standards of quality. Every mag drive pump is functionally tested to insure integrity of operation.

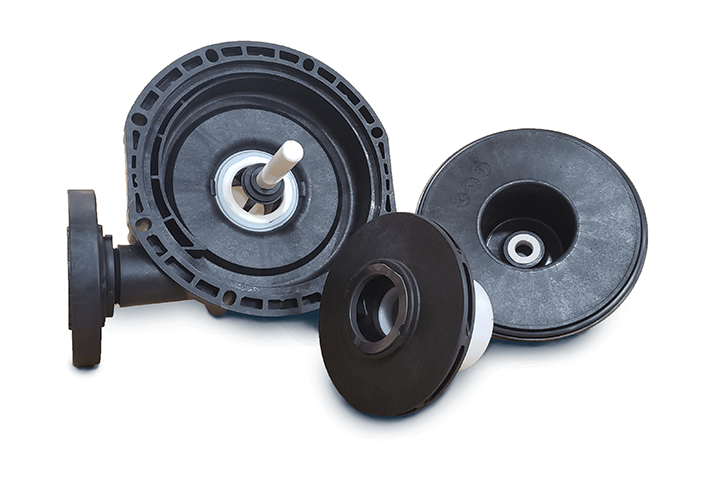

Flange Assembly

- All models 1/2 HP and up come with RF type adjustable flanges. The orientation of the flange can be varied to match corresponding bolt holes to facilitate piping installation. The new design can also help to eliminate leakage problems caused by flange deformation.

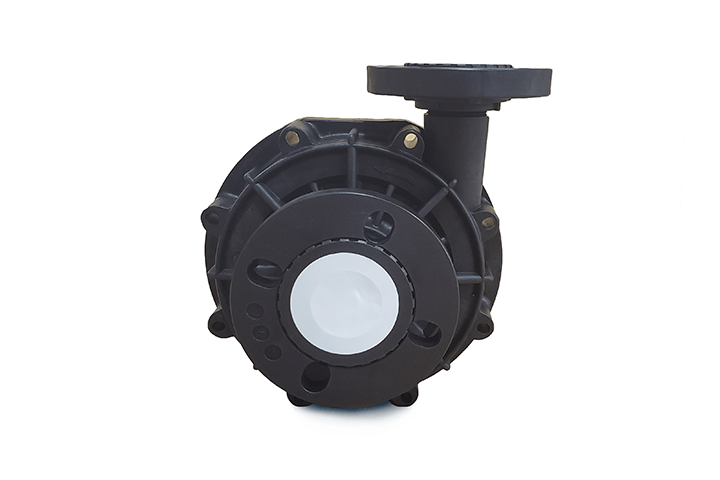

High Efficient Flow Design

- The geometry of the impeller and casing are generated through a hydraulic design program. In addition, Computerized Fluid Dynamics (CFD) is used to control the fluid stream pattern, thus reducing hydraulic loss and increasing pump efficiency.

High Performance Magnetic Coupling

- We utilize magnetic field analysis to calculate magnetic torque and maximize magnet utilization to ensure sufficient torque margin to prevent decoupling.

Integrated CAD/CAE System

- Using fully computer aided design and analysis to assist product development, modern design concepts help T-Mag products reach the highest technical levels in the industry.

Integrated CAD/CAE System

- Using fully computer aided design and analysis to assist product development, modern design concepts help T-Mag products reach the highest technical levels in the industry.

Patented Buffer System

- Our innovate dynamic buffer is specifically designed to absorb vibrations and shock caused by adverse operating conditions. At the same time, the dynamic buffer is self-adjusting, allowing a better face-to-face contact between the thrust ring and the wear ring, thus minimizing wear and prolonging service life.

Patented Dry-Run Design

- The revolutionized bearing design with dual-channel circulation on both inner and outer surfaces of the bearing contributes to rapid heat dissipation. The circulation leakage of the sealless pump is fully utilized to reinforce convectional heat transfer to thermally balance internal temperatures and prevent damage even under dry running conditions.

Patented Heat Dispersing Flow Path

- Pumps in the 1/2 HP through 5 HP sizes come standard with a patented additional fluid flow path around the bushing. This additional path allows the process fluid, or air, to cool the bushing of the impeller from the outside, while continuing to offer the internal spiral cooling channel. This unique feature prevents the heat build-up that so often damages or completely disables the shaft bushing.

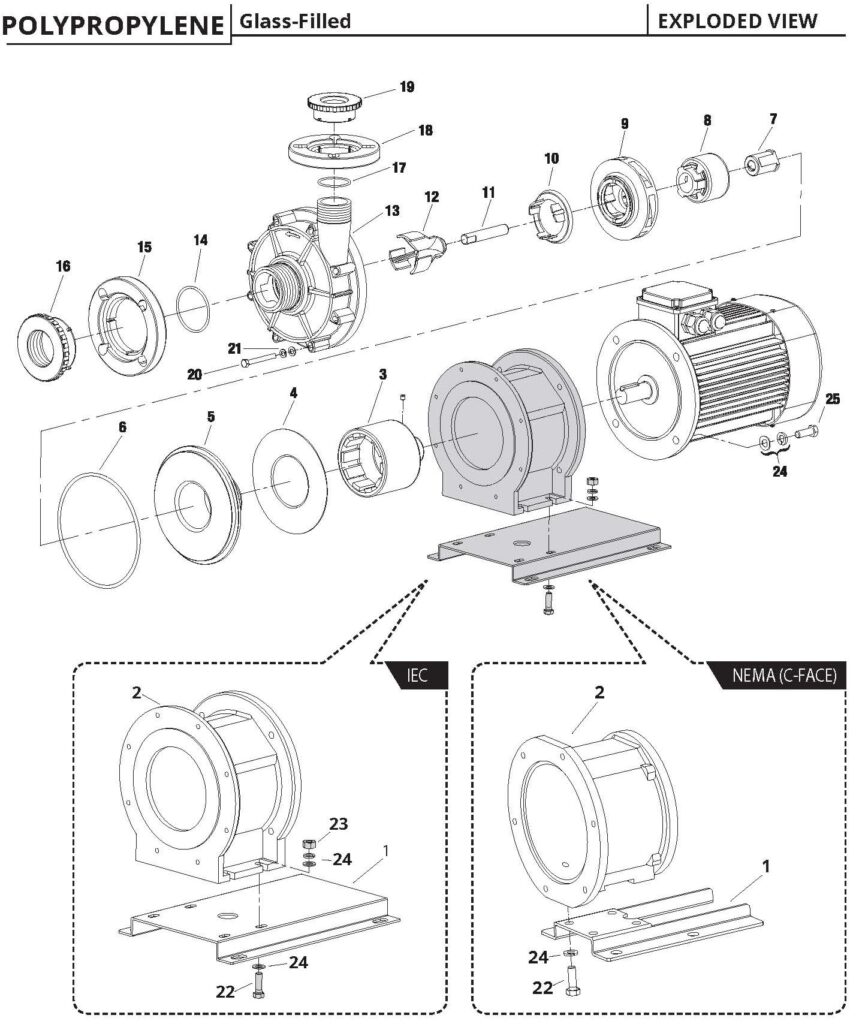

Casing Materials

- Glass-Filled Reinforced Polypropylene

- Carbon-Filled Reinforced ETFE

Elastomer Options

- Viton

- EPDM

- Teflon® Encapsulated Viton

Connection Options

- Threaded RF Flange (Standard)

- BSP Thread

- Straight Pipe Thread

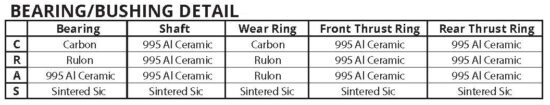

Internal Material Combinations

Animation of the patented heat dissipation technology that is in all AMX Series Magnetic Drive Pumps.

Video of our patented buffer system in action, as you can see the impeller and inner magnet bounce off the front buffer. The buffer acts as a shock absorb-er, which prevents catastrophic failure during harsh operating conditions, such as cavitation. This is a standard feature on all T-Mag AMX Series Magnetic Drive Pumps.

<div class="wp-block-contact-form-7-contact-form-selector">